Resource management is designed to show you how your time and money are being spent. Track, equipment, labor, materials, and vendor information—including details, rate, and history. Apply these resources to your work activities for accurate cost accounting. Enter details through the time sheet or by using the Distribute Resources command. All entries are recorded in the Resources log.

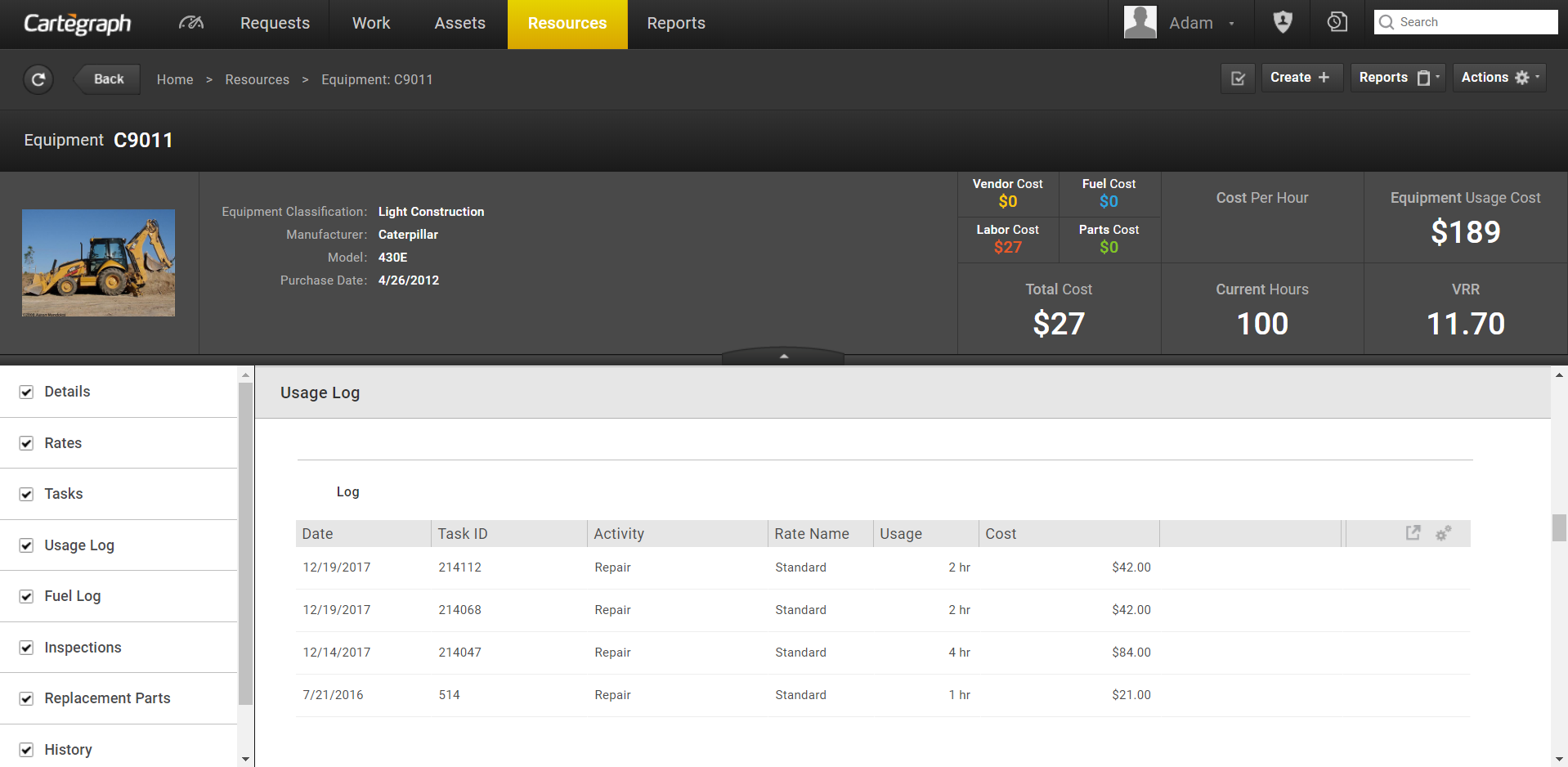

Equipment

- Equipment is a resource used by Tasks. Trucks, earth moving equipment, snow plow blades, and lawn mowers are examples you may choose to track as equipment. All equipment must have a valid rate so that costs can be calculated.

- Normally, equipment uses and rates are entered as mileage or hours.

- The Details, Rates and History sections can be updated.

- The Log section cannot be changed.

- The History section can be customized.

- Time sheet entries populate the Log section.

- Equipment rates help calculate Task costs.

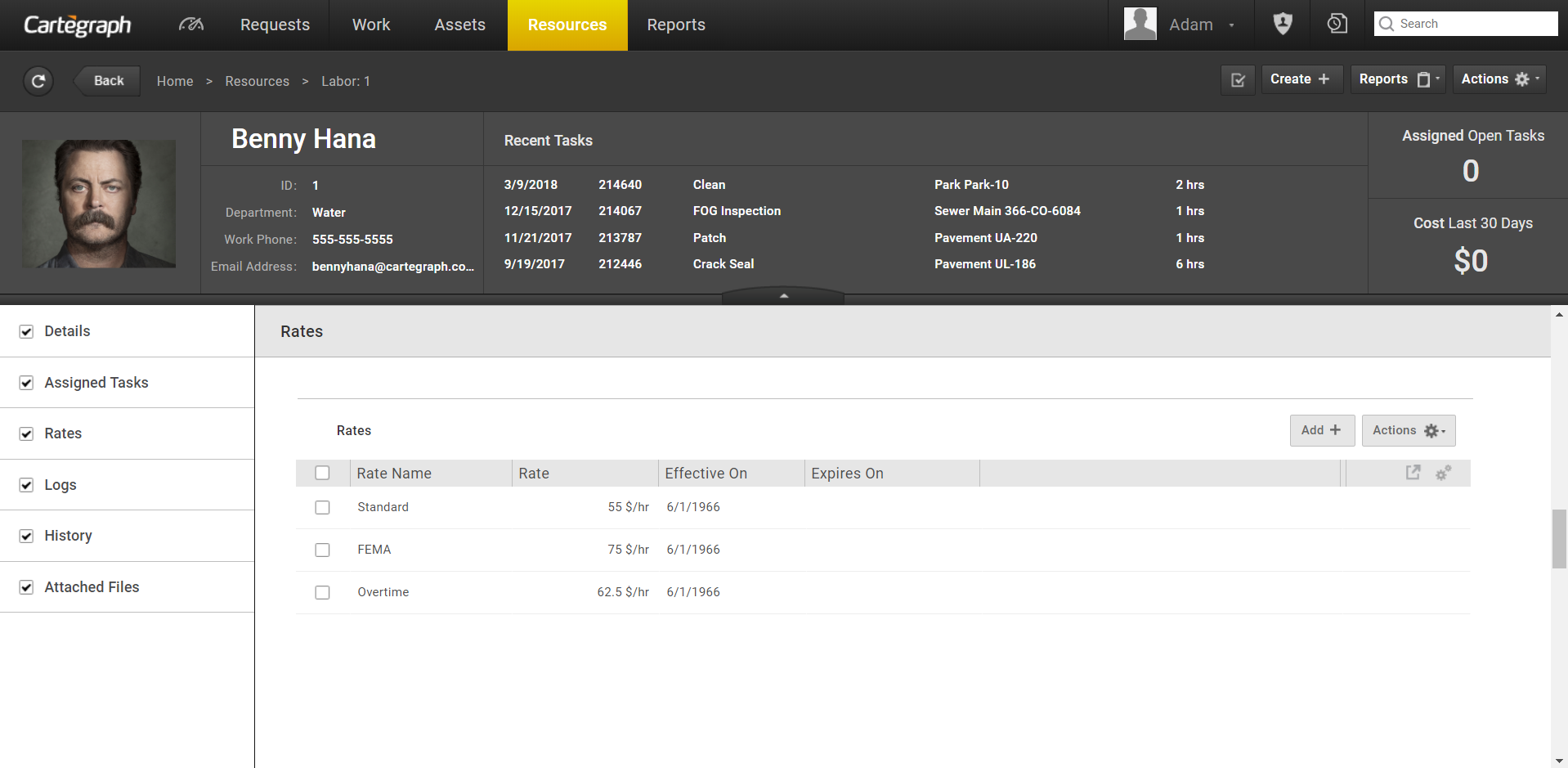

Labor

Labor is a Resource in Cartegraph where the time spent by people is tracked to tasks. Labor costs are part of the overall costs of tasks and assets. The following are key things to remember:

- For each labor record to work in the system it must be tied to a user account, and have at least one valid rate.

- Be sure to include an email address and smartphone number in the records detail to receive notifications.

- Task assignments are applied to labor records, and all-time entries should be made using the Time sheet or Distribute Resources task.

Labor Assignments

Quickly filter tasks with assigned labor assignments to follow through with the appropriate people or make assignment changes.

Assigned Labor is a collapsible section at the bottom of the Task tab’s layer panel.

The three filter options are:

- All displays any task with at least one labor assignment.

- None displays tasks without labor assignments.

- Custom displays tasks assigned to selected labor records, usually yourself or for a supervisor to select members of a group or crew.

- There must be at least one task layer for this feature to activate.

- The Custom option expands the Assigned Labor section to add, select, and remove laborers.

- Select or clear the laborer’s check box to include or exclude the laborer.

- The Assignment Queue works as an OR filter.

- The photo associated to the Assigned Labor is the photo in the user account record or primary attachment.

- The labor record must be associated to a User Account.

- Assignments are stored in the child recordset to the Tasks recordset.

Labor Rates

- Labor and Equipment rates are required to calculate Task costs.

- Rates are valid for a specific period of time.

- Each Labor or Equipment ID may have rates with different rate names. For example, Labor may be charged at a different, higher rate when performing specialized tasks like crane operation.

- Overtime and holiday rates are separate Labor rates which can be adjusted according to your organization and setup for individual laborers.

- Rates with the same name may not have overlapping effective dates. The old rate must end the day before the new rate takes effect.

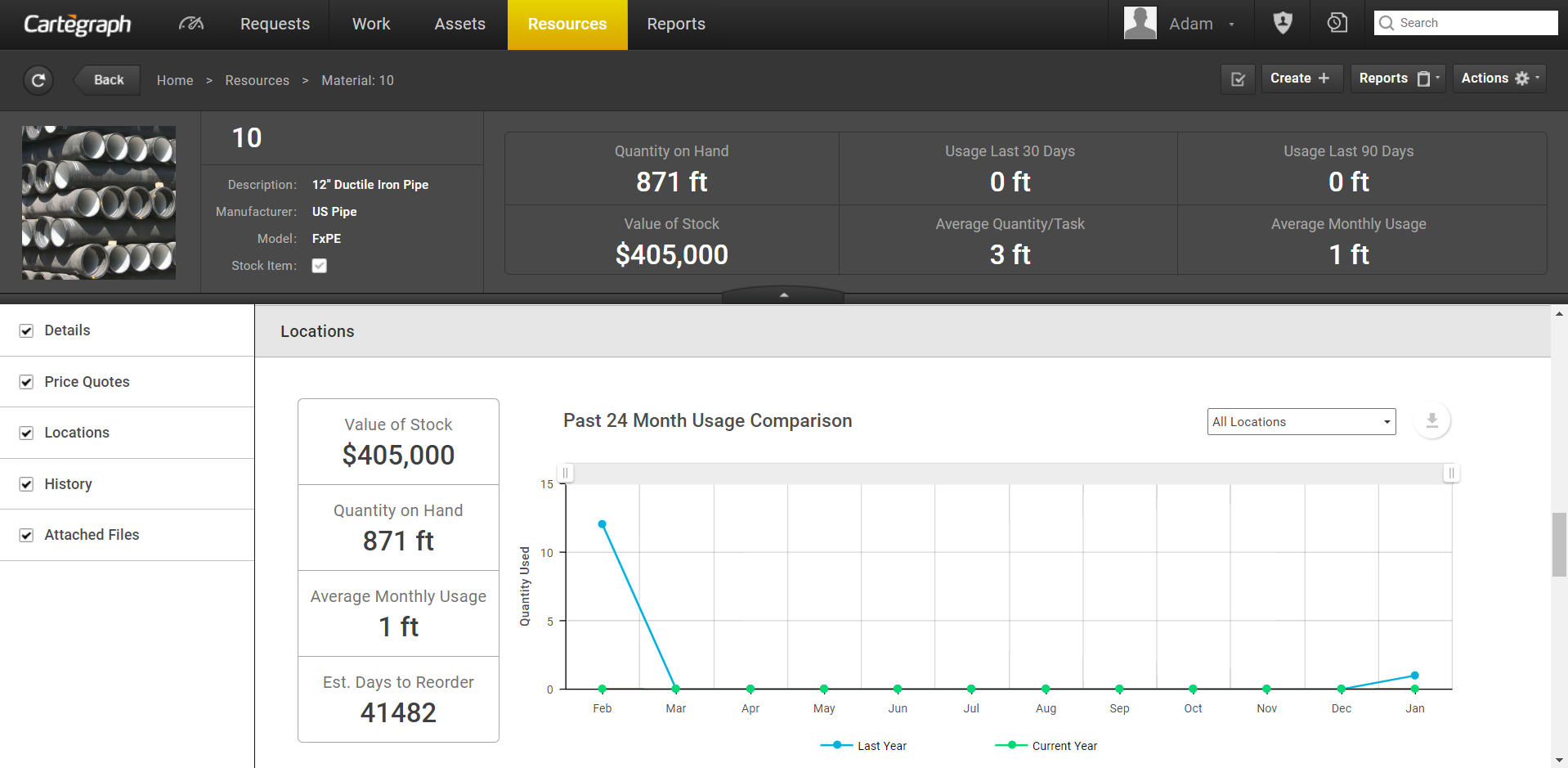

Materials

Materials are the supplies used to do tasks in your organization. As you enter the materials used on a Task the cost is calculated and the quantity on hand is adjusted.

- Enter an unlimited number of Material logs records.

- If a material has any default settings, those values display when added as a resource.

- If a material is marked as a Stock Item, and a Material log entry is added or removed, a quantity-on-hand adjustment is made.

- If the organization is using the Advanced Resources extension, then Material Location is required when entering a stocked Material.

- On the Material detail view, the Locations section shows just locations where the material is stocked. The display can be filtered by location.

- A material can be added more than once a day on a Task with the same or different price per unit.

- Valid dates for entry are the Task’s Actual Start Date and Actual Stop Date time span. Estimated dates are not considered.

- To use a Stock Item material on a Task, the material quantity on hand must be at least the amount used.

- The Entry Date is used for material inventory calculations.

- Used log entries removed from Time sheets are unassociated from the task. An increase adjustment is made with the log’s quantity and price per unit. A note is added to the increase adjustment similar to Record added as a systems correction for a deleted transaction.

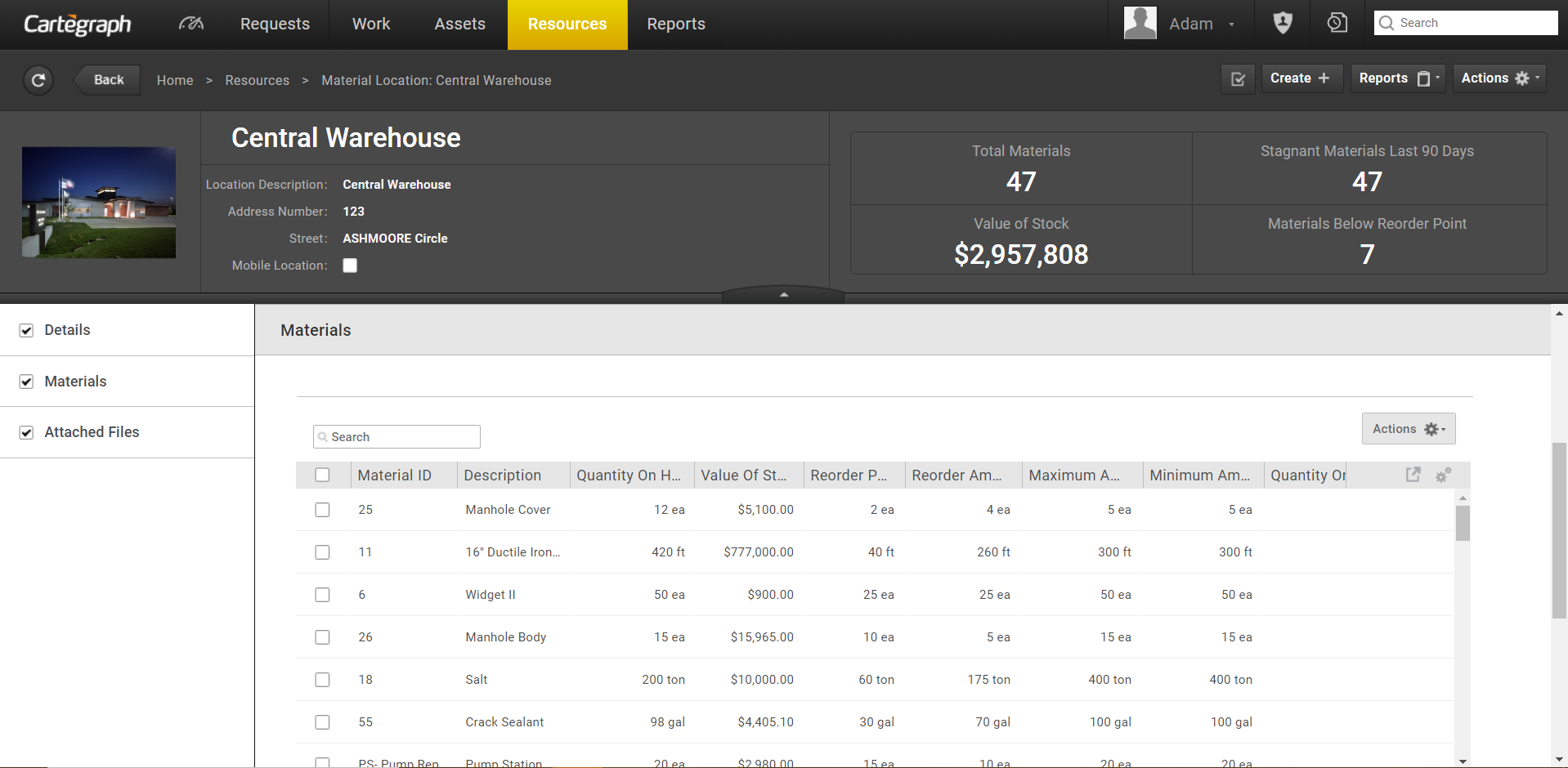

Material Locations

Material Locations are used to designate physical locations where materials are stored for your organization.

Materials are supplies used by your organization to do tasks. Examples of Material Locations include warehouses, storage yards, supply offices, sheds, and trucks.

- Organization must be using the Advanced Resources extension to Cartegraph to take advantage of Material Locations.

- Material Locations are a resource similar to Labor, Equipment, Material, Vendors, and Orders.

- Use Library Filter Administration to set a default Material Location for your role.

- Only Materials that are stocked may have their inventory allocated by location.

- When resources are entered on the time sheet, the location of the material is entered at the time the material is entered. The quantity on hand at the selected location is displayed to aid the user in posting material to the time sheet.

- When entering a stocked Material on a time sheet the used amount must be less than or equal to quantity on hand at the designated location.

- When a Quantity on Hand Adjustment is performed, the Material Location is required. The current stocked total and the future stocked total will be shown to the user as they are performing a stocking, transfer, increase adjustment or decrease adjustment.

- Material Location detail view shows statistics and details for all materials stocked at the location.

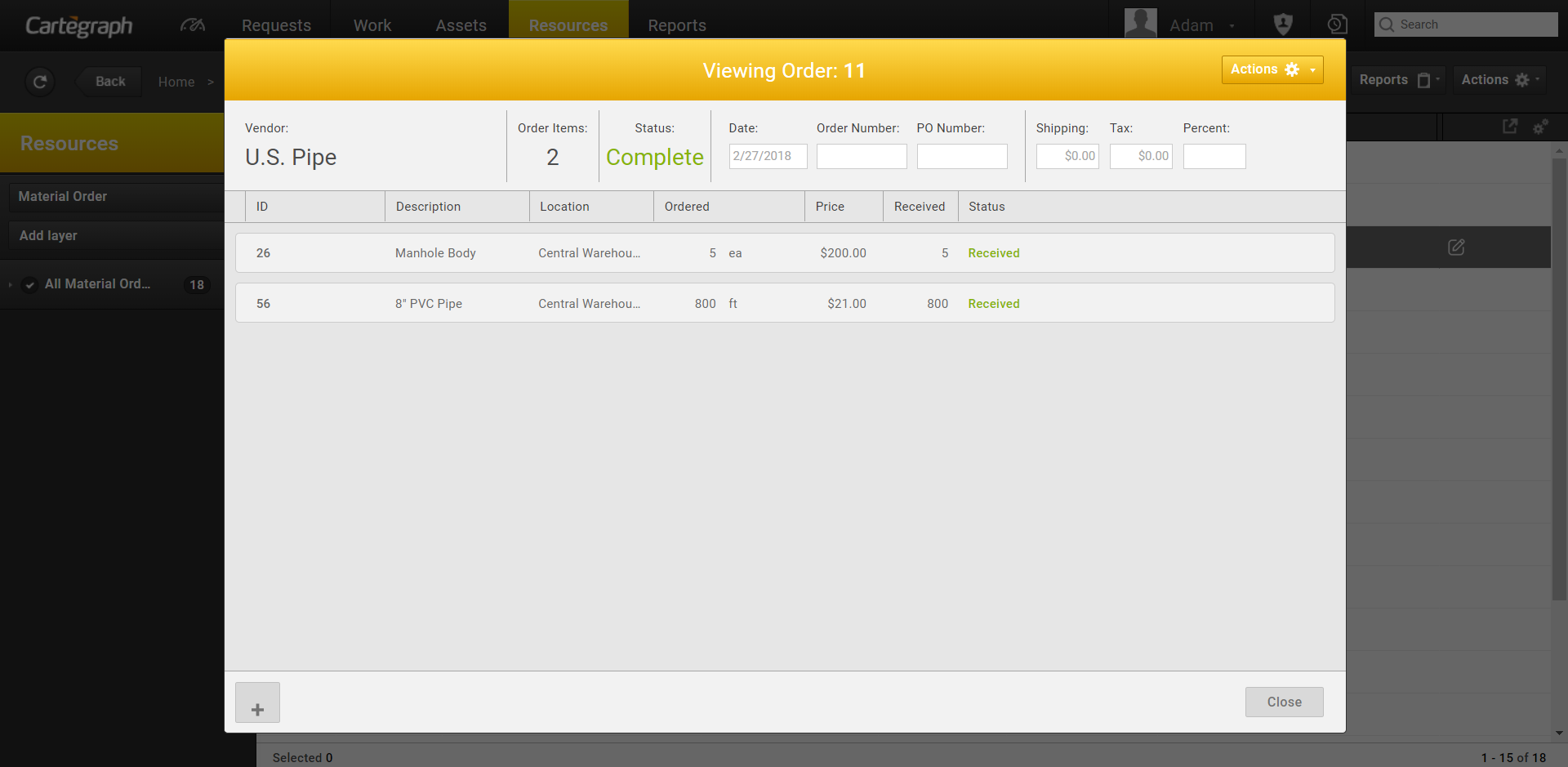

Material Orders

Material Ordering allows your organization to Order and Receive Stock Materials for a given Location within the organization.

Material Ordering includes the following options:

- The system reports what materials are below the reorder point.

- Place orders

- View and edit existing orders

- Receive and stock orders

- Reports:

- Quantity on Hand per Location

- Location

- Orders

The Material Orders list view is the entry point into the Material Order process. All existing orders for you display on this view.

From here you can to do any of the following:

- Create Orders by clicking Create.

- View and Edit Existing Orders by clicking Edit on individual order Items.

- Receive Orders by selecting the open order in the list and select Actions>Receive.

- Delete Orders by selecting the order Item in the list select Actions>Delete.

Material Inventory

There are three ways to adjust material inventory’s quantity of hand for any material marked as a Stock Item. In the Material record’s Detail view, select Stock or Increase Adjustment to increase the quantity on hand or Decrease Adjustment to decrease the quantity on hand. If the organization is using the Advanced Resources extension, Material Location is required when performing one of these actions.

This quantity on hand adjustment entries are listed in the logs in the Material detail view as stocked, increase adjustment, or decrease adjustment transactions. Once the entries are made, they cannot be edited. Make another entry to adjust the quantity. Quantity on hand updates when an entry is saved. This setup is not editable by users.

The total quantity on hand for the material is listed in the header of the Material record. This is a total of the quantity for all locations.

Inventory Fields

These fields help in determining whether a material is ready for Ordering for a location or a material is below the minimum amount to get refilled.

These fields are:

- Reorder Point-a point after which material is ready to be ordered for a location.

- Reorder Amount-default amount to order when reorder point is past.

- Set these fields for each material from the location page.

- Minimum Amount-minimum threshold set after which to refill the truck.

Each Stock material should be stocked at a location.

For example, Lead is stocked at East warehouse and West warehouse.

The Reorder Point is set at 5 lb for East warehouse while 9 lb for West warehouse; lead at West warehouse gets used more than East warehouse.

The Reorder Amount is set at 25 lb and 45 lb respectively.

Once material’s quantity on hand falls below the reorder point. For example, quantity-on-hand is 4 lb for East and 8 lb for West warehouse, these materials display on the Ordering screen with Reorder amount defaulted to 25 lb and 45 lb respectively.

NOTE: Setting them from the material page wouldn’t work because materials at different location could have different values for these.

Inventory Methods

There are many ways to value inventory and determine the cost used when items are used for task activities. Your organization’s accounting department determines your inventory valuation method.

NOTE: The material log transaction reflects the use of the specified quantity at a total cost. The total cost is determined by the inventory method selected for the material. The Cost per Unit (CPU) shown for this transaction is the total cost divided by the quantity. Once an inventory method is selected for a material, it cannot be changed if logs have been posted to the material.

Cartegraph recognizes the following inventory methods:

- FIFO (First in, First Out): Items are used at the price of the oldest inventory item.

- LIFO (Last in, First Out): Items are used at the price of the newest in inventory.

When LIFO or FIFO calculations are based on the date of the transactions. When two transactions have the same date, the system uses the first date encountered.

- Most Expensive: The most expensive items are used first, regardless of when the items were received into inventory.

- Least Expensive: The least expensive items are used first, regardless of when the items were received into inventory.

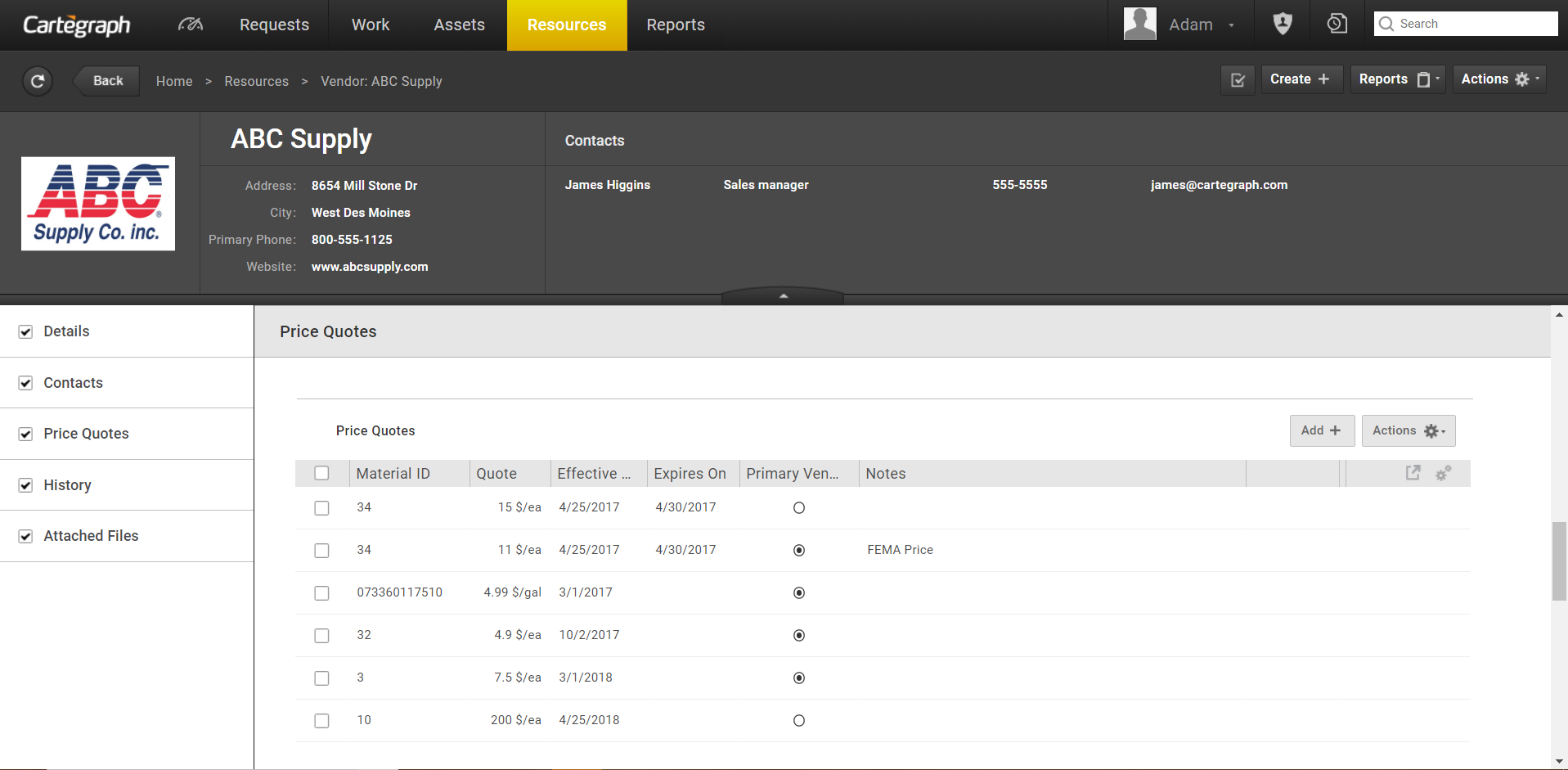

Vendors & Receipts

Vendors are part of Resources in the Cartegraph system.

Vendors are the companies or individuals that provide services or inventory to your organization.

- Store Vendor contact information and price quotes in the system to make managing your services and inventory more efficient.

- The vendor price quotes help you track the cost of an inventory item at the time of purchase. As prices can vary overtime, these fluctuations are tracked when capturing asset and task costs.

- If your organization uses Material Orders, the vendor is key to placing and managing orders.

User Interface

- Analytics Dashboard

- Navigation Persistence

- Global Search

- Table of Contents/ Layers

- Map Tools

- Documents Attachments

- List View Data Export

- More Information…

Request Management

Work Management

- Work Orders

- Repeating Work Orders

- Tasks

- Activities

- Task Calendar

- Time Sheets

- Distribute Resources

- Task Triggers

- Preventative Maintenance

- More Information…

Asset Management & Analytics

Resource & Inventory Management

Report Management

Mobile Management

- Cartegraph for iPad and Cartegraph One Feature Comparison

- Cartegraph for iPad

- Cartegraph One

- More Information…

Workflow Management

System Management

- Structure Manager

- Library Manager

- Layout Manager

- Esri and Active Directory

- Security Role Administration

- System Licensing

- System Requirements

- More Information…